Petroleum Tester

Category Archives:Petroleum Tester

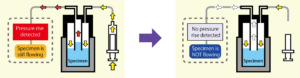

Automatic Colorimeter for Petroleum Products acl-3

acl-3 automatically determines 4 kinds of Colors – Saybolt, ASTM, Pt-Co/Hazen, and Gardner Colors, utilizing the Tri-Stimulus values from the spectroscopy method prescribed in ASTM D6045, which generates equivalent test results with conventional manual precision in about 5 seconds. Since no subjective judgment needs to be called, perfect traceability is achieved.

![]()

Specifications. CATALOG

| Test Methods | ASTM Color : ASTM D1500, D6045, ISO 2049

Saybolt Color : ASTM D156, D6045 Pt-Co / Hazen Color : ASTM D1209, D 5386, ISO 6271 Gardner Color: ASTM D1544, ISO 4630 |

|---|---|

| Measurement Method | Tri-stimulus values from the spectroscopy method |

| Photodetector | CMOS Linear image sensor |

| Measuring Wavelength | 400nm to 700nm, 10nm interval |

| Light Source Lamp | White LED (Lifetime: approx. 20,000h) |

| Display Panel | 5.7 inch TFT color LCD Touch Panel |

| Interface | USB port (for communication with PC)

USB memory (for file system: FAT32) Parallel port (for printer) |

| Size (W x D x H) | 540 x 383 x 255 mm |

| Weight | 15.5 kg |

| Power Consumption | AC 100 to 240 V 40 VA (max) 50 / 60Hz |

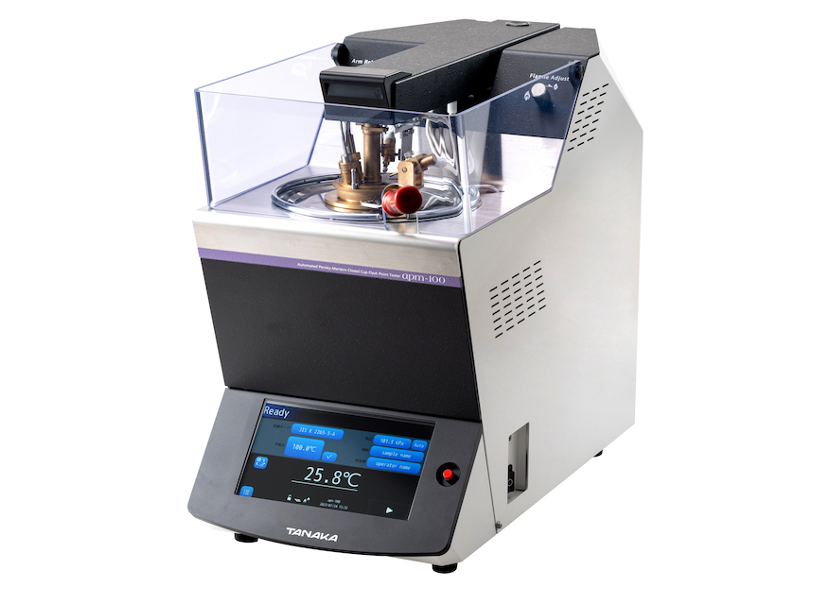

Automatic Pour / Cloud / Freezing Point Tester mpc-6

Tanaka’s new Automatic Pour / Cloud / Freezing Point Tester mpc-6 is designed with “Simple, Reliable, and Robust” concepts. It requires a mere 4.5 mL sample and provides quick, automatic, and high-precision determination of 3 key cold property measurements.

INNOVATIVE

Tanaka’s original mini-test methods require much less

sample volume (4.5 mL) and short testing time compared to

conventional manual methods

SMALLEST FOOTPRINT

A very small width of 16 cm allows for the most efficient use of bench space.

3-in-1

Test pour point, cloud point, and freezing point with just one instrument. Pour and the cloud can be run simultaneously in a single run.

Eco-friendly

Equipped with CFC-free cooler achieving low noise, low vibration, and energy-saving. A sample temperature of -90℃ can be reached without an external chiller.

● Intuitive 7-inch Touch-Screen Operation: Simplicity ensures smooth operation.

● Extremely Simple: Set the sample cup, input the expected points, and then press START. The pre-heat and cooling sequences are run automatically. Pour and cloud point results can be obtained in a single run.

● Search Mode for Unknown Samples: The new SPE mode will test pour points with different pressures so parameter optimization can be easily done.

● Data Connectivity and Management: Ethernet can export data to LIMS or an optional printer. Up to 50 data can be stored securely with a password.

![]()

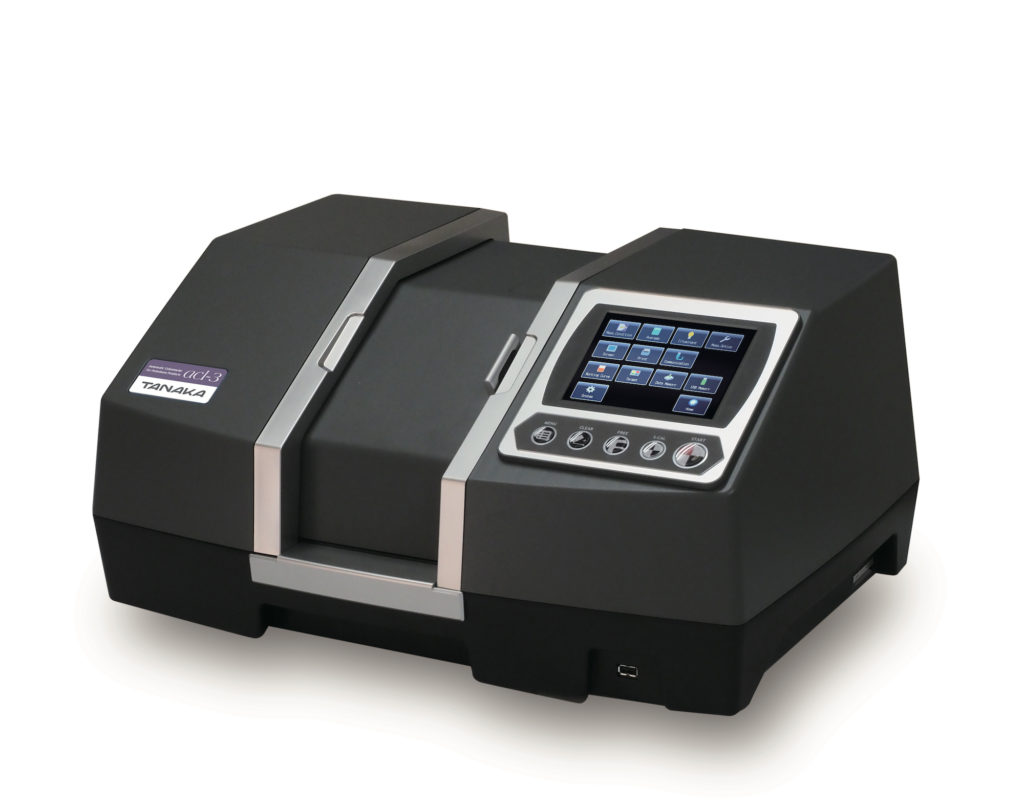

Automated Pensky-Martens Closed Cup Flash Point Tester apm-100

NEW

series 100

Since 1966, we have provided automated flash point testers with reliable results and high productivity to customers worldwide.

10 years have passed since the release of the 8 series, and the model has been changed from apm-8 to apm-100.